Know-How

TOOLS

Modern machinery and high level of automation

Our modern machinery in Burbach and Torgelow

Our technological strength is based on modern machines and a high level of automation at our sites in Burbach, North Rhine-Westphalia and Torgelow, Mecklenburg-Western Pomerania. We have a production capacity of up to 7,500 tons per year and an own dedicated maintenance team that ensures a seamless production. Investments in our machines guarantee high operational readiness and delivery capability.

Openess towards new technologies

Since 2021, we are leveraging a technological innovation in our sawmill production department, including an automatic cut-off machine for the precise cutting to length of tubes in carbon steels and stainless steels in large batch sizes. Our extensive machining equipment is complemented by close collaboration with technology partners to develop customised solutions for our needs. Fully automated parts feeding ensures competitive products "made in Germany".

You want to test our know-how?

Tools

Our high-tech presses set standards

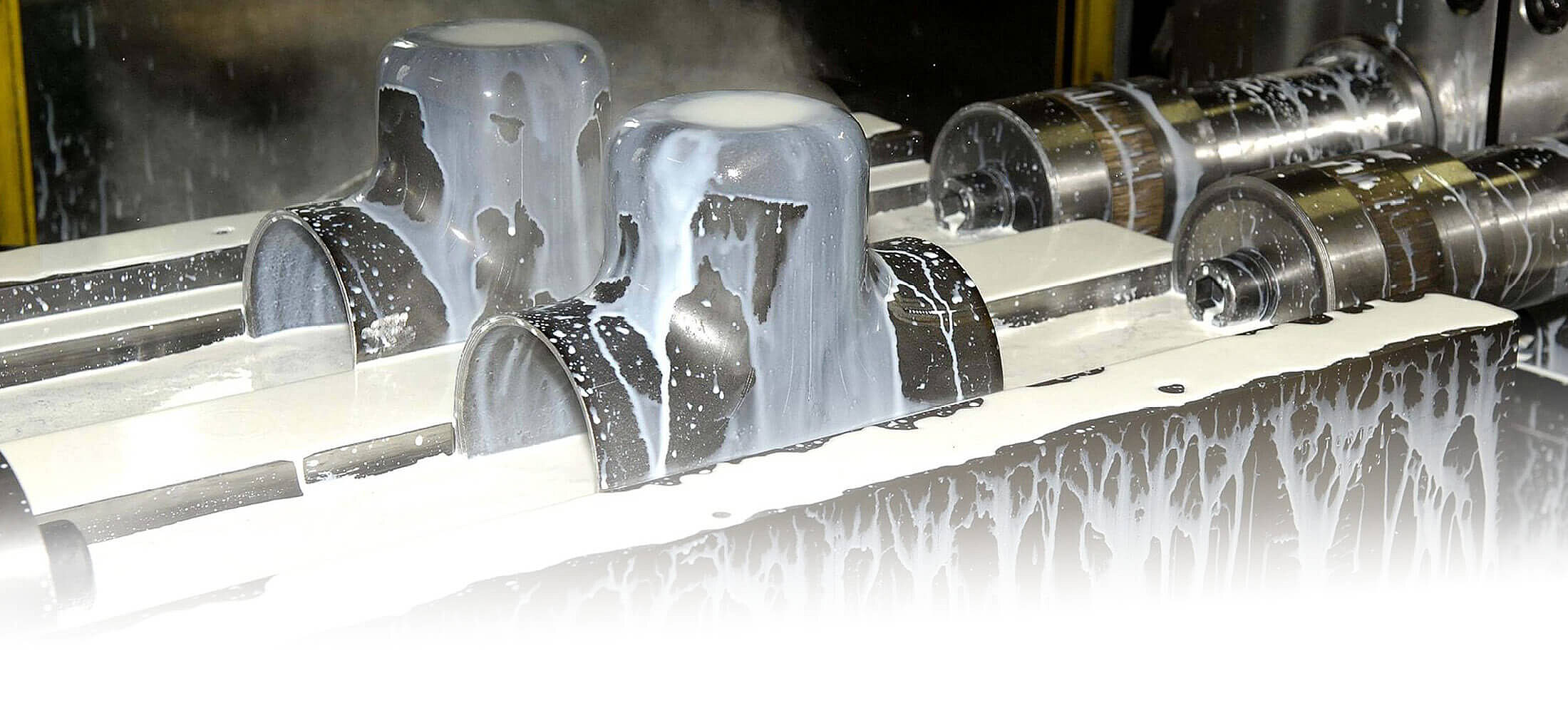

Innovative cold forming

For forming, we mainly rely on cold forming (hydroforming). At Busch + Kunz, we have three modern hydroforming presses with a combined pressing force of up to 8,000 tons. Our hydroforming presses are equipped with modern electronic machine controls to ensure a smooth production and a consistent quality level.

Precise warm forming

We also carry out hot forming for T-pieces and reducers using modern 4,000 and 8,000 kN hot forming presses with counter-pressing equipment. The forming temperatures of the pipe sections range between 850 - 920 °C.

Our key to guaranteeing high material quality

The material changes that occur in both forming methods require the workpieces to be normalised in order to restore the necessary material qualities. This takes place in one of our four annealing furnaces at both of our sites and is carried out at annealing temperatures of 920 up to 1,050 °C depending on the material. The annealing curves are specified by us and delivered by control technology connected to our furnaces. The curves get digitally documentedfor later tracking purposes. Samples from the individual batches are analysed and evaluated in a nearby external laboratory.

Quality and transparency in every detail

You can easily recognise a Busch + Kunz product by the fact that all products are finally blasted (carbon steel); a product feature that Busch + Kunz introduced over 30 years ago. Our stainless steel products are pickled for us by a specialised nearby located company. Our production is characterised by the fact that we produce in batches and can trace the tube used and its origin, including the works certificate, for every product sold, even years later. We have had our production processes, technologies and offered material qualities of our products independently audited and testified by the general technical inspection service in Germany (TÜV) through a complete process audit.

Tools

Hydroforming and warm forming - methodes in more details

Cold forming and hot or warm forming are two different processes for manufacturing components with precise shapes. In cold forming, the forming process takes place at room temperature, whereas in hot or semi-hot forming, high temperatures are used. Both processes offer specific advantages and areas of application.

Hydroforming - delivering an efficient production of welding fittings

In hydroforming, the cut pipe section is inserted into the lower mould and the 2-part mould is closed. The axial punches are used to seal from both sides and fill the mould with the pressure medium. In the actual forming process, the punches compress the blank, while the moulding medium expands at the same time and is brought into contact with the mould wall. The workpiece is formed with the calibration pressure so that its contour corresponds exactly to that of the tool. Finally, the mould is opened and the component is automatically removed. Some of the advantages of hydro-forming are repeat accuracy, better end-product surfaces and subsequently less machining.

Warm forming - an established production method of welding fittings

In hot or warm forming, the red-hot raw part is placed in a die. When the press closes, the red-hot material to be formed is pressed into the die - the material flows into its predetermined shape. The counter-pressing device is used to draw hot-pressed T-pieces and to eject the formed component. The finished component can now be removed. In the case of hot production, the reproduction of greater wall thicknesses is an advantage over hydro-forming due to the lower forming forces required.