Know-How

PROCESS

Quality as a result of effective processes

At Busch + Kunz, we are proud of having in-depth knowledge and expertise in our industry. Our knowledge and experiences are the result of years of continuous hard work and constant improvement of our processes.

Our processes are the backbone of how we run our company. They are carefully planned and constantly optimized to ensure maximum efficiency and productivity. Each process is an integral part of our company and contributes to providing our customers with outstanding products and services.

Our processes are designed to be flexible and adaptable. This enables us to react quickly to changes in the market or in our customers' requirements. Our expertise ranges from project management to product realization and customer support. We are constantly working to expand our knowledge and keep up to date so that we can continue to offer our customers the most innovative solutions in the future.

You want to test our know-how?

Process

Shopfloor management at Busch + Kunz

To support and promote transparency and communication, we rely on the shop floor management methodoloy within our organisation. Effective shop floor management helps to identify bottlenecks, shorten production times, reduce costs and increase overall productivity. It involves establishing clear communication channels, regularly reviewing performance indicators and implementing continuous improvement measures. Our shop floor management also contributes significantly to the motivation of our staff in the shop, as they are constantly involved in improvements. Their feedback in particular is crucial for future changes in the processes.

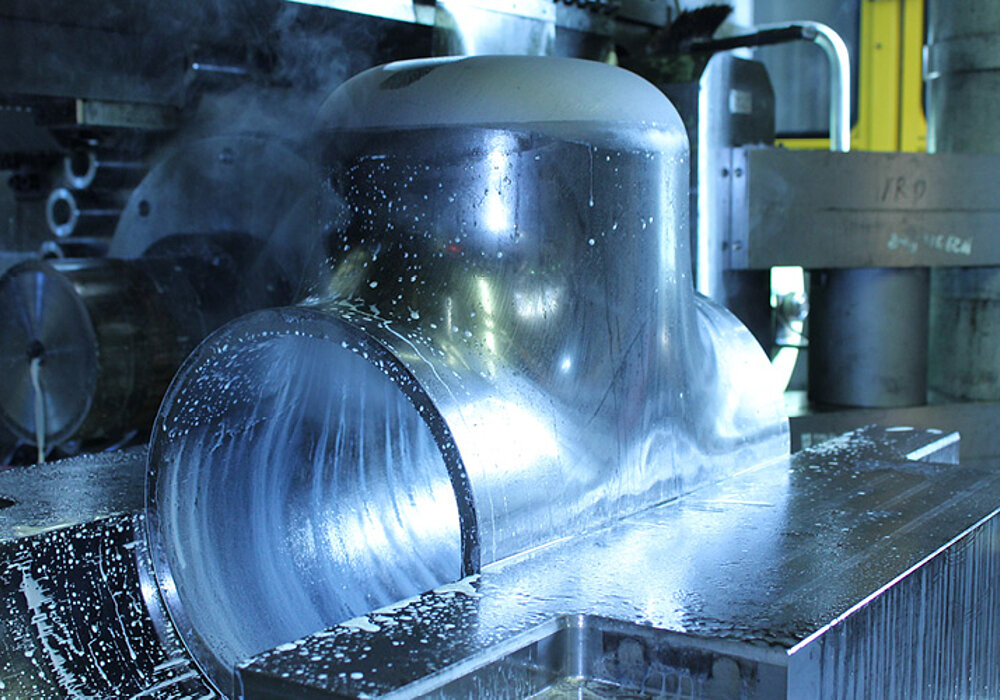

Our quality assurance - more than just testing

Our quality starts already with our procurement. We source raw materials from quality suppliers in Europe, mainly in Germany. Long-term supplier relationships create trust and security of supply. Our employees are trained and test according to specifications. The quality management team ensures high standards through in-process inspections. We fulfil AD 2000 W0 and are ISO 9001 certified, also in accordance with directive 2014/68/EU Annex I 4.3 for pressure equipment. Quality is our focus to satisfy customers.

Traceable origin and certification of our products

Our products are produced in batches so that we can also trace the origin of the raw material for every item produced and sold in the future. We offer our own products with certification either in accordance with EN 10204 - 3.1 by a factory expert or tested and validated by the German technical inspection service (TÜV) in accordance with EN 10204 - 3.2. The non-destructive testing of the components is carried out internally by qualified personnel in accordance with ISO 9712. All other metallurgical tests are carried out for us by an accredited materials laboratory.

Tools

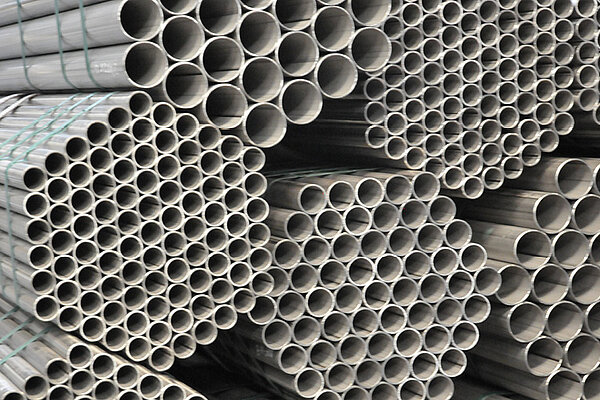

Our standard is fullfilling the needs of our customers

In our finished parts warehouse at the Burbach site, we have a storage capacity of over 1,500 tons spread over 3,500 storage locations. With a comprehensive range of over 2,000 different product articles that we always have in stock, we can process customer enquiries quickly and efficiently. Our customers rely on our proven warehouse infrastructure and our many years of experience.

Our shipping team is one further element of the value we create for our customers. We are proud to have a team of highly motivated employees who are passionate about their work for our customers. Team spirit is at core of their daily working routine, as we know that satisfied employees are the basis for outstanding performance. We understand that every order and every customer is unique. Our shipping team is ready to offer customised solutions that meet the individual needs and requirements of our customers.